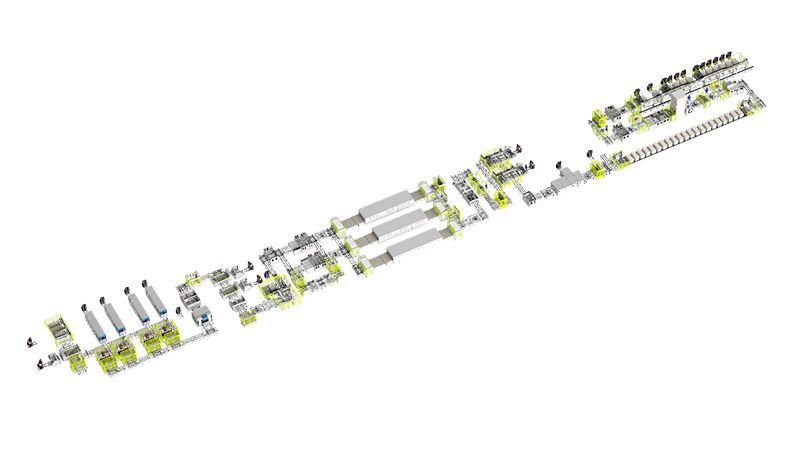

Automatic Framing Machine

Used for automatic silicon dispensing and assembling of solar panel frames

The automatic framing machine features short cycle time and high precision and can meet panel production requirements. The corner misalignment, the leaking hole dislocation and the border-corner clearance are all within 0.3mm. A shorter panel-switching time also improves production efficiency. And the HMI provides two languages of Chinese and English to meet different customer demands.

Technical Parameters

| Item | Parameters |

| Panel size | (1,680-2,650)*(992-1,500)mm |

| Cycle time | ≤20s |

| Panel corner misalignment | ≤0.3mm |

| Leaking hole dislocation | ≤0.3mm |

| Border corner clearance | ≤0.3mm |

| Switch Time | ≤1-2h |

| Alignment mode | Cylinder alignment, servo switching |

| HMI languages | Chinese and English |

| Overall dimensions: | 3,300*2,450mm |

| Voltage | 3 phase 5 wire 380V, 50Hz, AC±20% |

| Power | 3.7kW |

| Air pressure | 0.6-0.8MPa |

Features

- Adding the frame gantry, higher than the conveying line, the frame can be placed in advance

- The force exertion is even to ensure the uniform glue application;

- 20 sets of suction cups complete the panel leveling without leaving marks on the glass;

- The framing machine is designed with profile straightening and pressure angle mechanisms to make qualified frames with accurate angles.

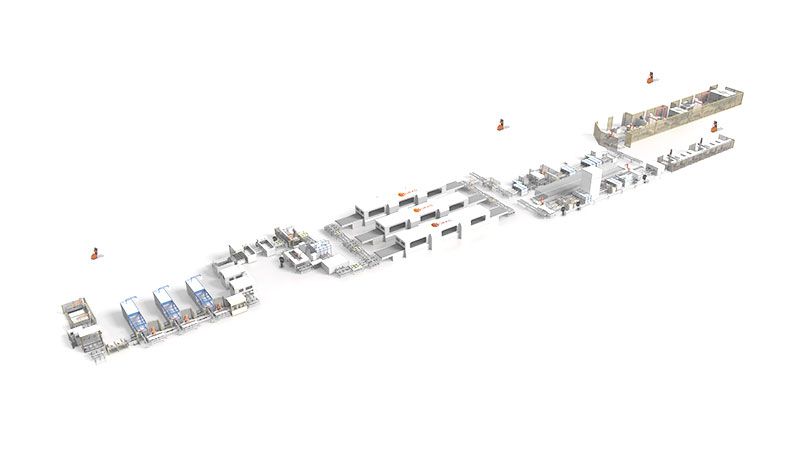

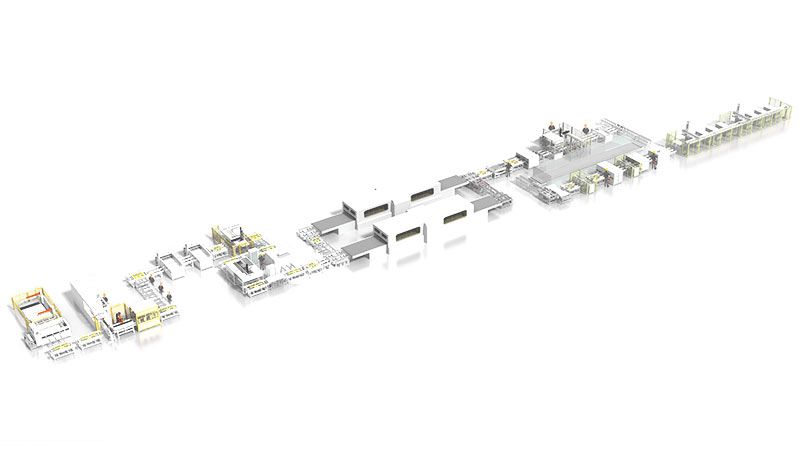

Horad, as a specialist manufacturer of intelligent PV panel production line, is committed to providing complete PV module manufacturing solutions for global customers within the photovoltaic industry like solar panel manufacturers. Our portfolio includes not only automatic solar panel production lines, but also individual equipment for PV modules production, from glass loading equipment at the beginning to solar panel assembly and testing equipment at the end. If you are looking for complete solar turnkey lines for photovoltaic module manufacturing, Horad will be your reliable PV solar panel line supplier.

Related Products

Get in Touch