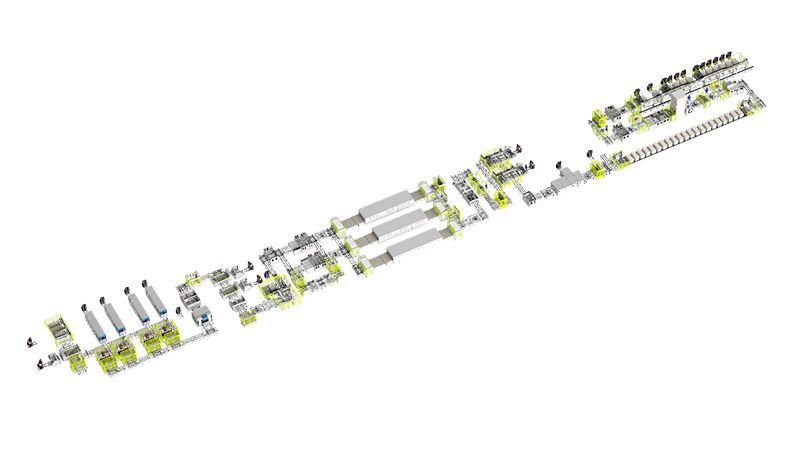

Double Layer & Triple Chamber Laminator

Solar panel laminator

Technical Parameters

| Item | Parameters |

| Effective lamination area | 2,700*8,700mm |

| Capacity | 250-300MW/year |

| Utilization rate | ≥99.5% |

| Maximum vacuum degree | 30Pa |

| Operating temperature | -180℃ room temperature |

| Precision of temperature control | ±1.5℃ |

| Temperature accuracy | ±1℃ |

| Heating method | Oil/electric heating |

| Cooling method | Water cooling |

| Compressed air pressure | 0.6-0.8MPa |

| Overall dimensions | 47,700*3,650*3,600mm |

Features

- Three chambers use rapidly circulating cooling water to cool down the modules quickly;

- The intelligently controlled and efficient cleaning system assists the unmanned lamination;

- Conducive to the cleaning of stains on the circulating high-temperature cloth;

- Strong compatibility of being suitable for a variety of solar module production;

- The upper and lower layers are independent from each other. Three chambers on each layer work together to ensure the stable and reliable transport;

- Effectively reducing the warpage and framing defects of PV modules;

- Other dimensions are also customizable as customers request.

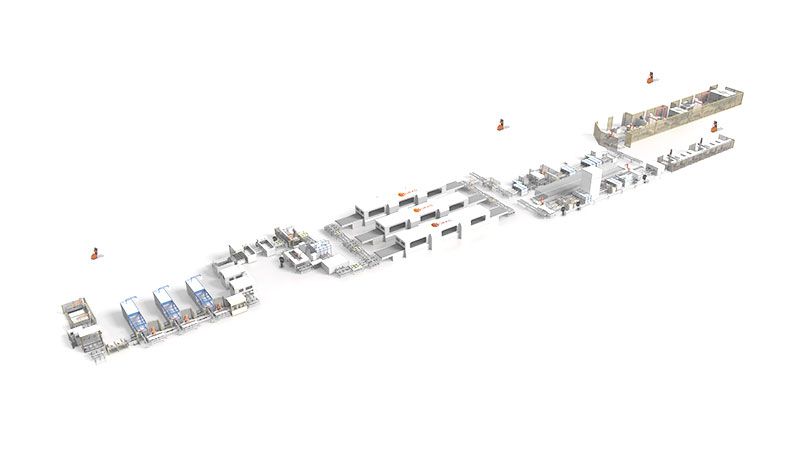

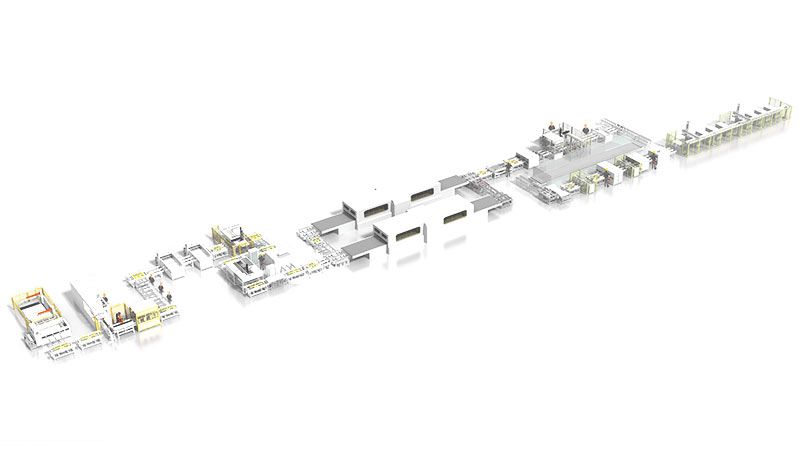

Horad, as a specialist manufacturer of intelligent PV panel production line, is committed to providing complete PV module manufacturing solutions for global customers within the photovoltaic industry like solar panel manufacturers. Our portfolio includes not only automatic solar panel production lines, but also individual equipment for PV modules production, from glass loading equipment at the beginning to solar panel assembly and testing equipment at the end. If you are looking for complete solar turnkey lines for photovoltaic module manufacturing, Horad will be your reliable PV solar panel line supplier.

Related Products

Get in Touch